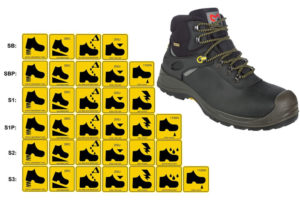

Since many people get confused about the difference between Safety Shoes, in this post, I will explain the difference between S1, S2, S3, and S1p. As much as you don’t want to risk getting injured on-site, in the workshop, factory, or at your place of work, it is important to know the difference between these safety shoes before you buy one. One of the frequently asked questions regarding safety footwear is the difference between S1, S1P, S2, S3 Safety footwear!

Also read: Important Reasons Why you Need Pinterest to Promote your Business

So, what’s the actual difference between S1, S1P, S2, S3 safety footwear?

1. S1 safety footwear

S1 Safety shoes with S1 certification have reinforced safety toes made of steel or composite, a closed heel, and an antistatic sole, With an energy-absorbent heel, you can work comfortably on every job.

S1 safety footwear basic properties:

- They have a Closed seat region

- Antistatic properties (including the “A” marking)

- Energy absorption of seat region (including the “E” marking)

- Resistance to fuel oil

Also read: 12 Best Ways to Free Up Storage Space on Windows

2. S1P safety footwear

S1P safety footwear is an S1 footwear plus and it has the following basic properties;

- It is marked “S” on the label.

- fully enclose heel

- anti-static ( A symbol)

- energy absorption in the heel area ( E symbol)

- upper resistant to water penetration and water absorption ( WRU symbol)

- Penetration resistance and ( “P” symbol).

3. S2 safety footwear

S2 Safety shoes with S2 certification have the same specifications as S1 certification and are also water-resistant. Safety footwear with S2P certification also has perforation-resistant.

S2 safety footwear basic properties:

- Closed seat region

- Antistatic properties (including the “A” marking)

- Energy absorption of seat region (including the “E” marking)

- Resistance to fuel oil

- Water penetration and absorption

Also read: 9 Most Deadliest Computer Viruses that Stood the Test of Time

4. S3 safety footwear

S3 Safety shoes with S3 certification have the same specifications as S2 certification plus a profiled outer sole. This gives you a very stable and comfortable footing while working on any task. Safety footwear with S3 certification always has a perforation-resistant insole.

When choosing your safety footwear, first of all, you need to know some descriptions coming from the norms. S1, S1P, S2, S3 safety footwear follow the UNI EN ISO 20345 standard:

UNI EN ISO 20345 = Personal Protective Equipment – Specifications for safety footwear for general use. Fit-out with toe cap, this footwear protects the user against crushing impacts with protection provided on 200J, and pressure loading of at least 15 kN.

General distinction between S1, S1P, S2, S3 safety footwear:

- If you work indoor, no risk of water sprays, and you need protection for your toes and good breathability, then you need S1 safety footwear

- If you work indoor, no risk of water sprays, and you need protection for your toes, you need protection against perforation and good breathability, then you need S1P safety footwear

- If you work outdoor and you need protection for your toes and against water sprays, then you need S2 safety footwear

- If you work outdoor and you need protection for your toes, you need protection against perforation, and against water sprays, then you need S3 safety footwear

What other features should I consider for my S1, S1P, S2, S3 safety footwear?

As you can see, the biggest difference between S1, S1P, S2, S3 safety footwear consists of the resistance to water sprays and the puncture-resistant plate. The S1P and S3 are basically S1 and S2 safety footwear, with an additional puncture-resistant plate.

Also read: Pegasus Spyware – The Most Intelligent Spyware Ever Built

Safety Shoe Requirements

Safety Footwear (marked “S” on the label)

This pair of footwear complies with the EN ISO 20345: 2011 standard. See table below

| Symbol | Requirements | Class | |||

| SB | S1 | S2 | S3 | ||

| – | Basic requirements | x | x | x | x |

| – | Fully enclosed heel | o | x | x | x |

| A | Anti-static properties | o | x | x | x |

| E | Energy absorption in heel area | o | x | x | x |

| WRU | uppers resistant to water penetration and water absorption | o | o | x | x |

| P | penetration resistant | o | o | 0 | x |

x = Requirement has to be fulfilled for this class

o = This may be a feature but is not an absolute requirement

Supplementary requirements for both standards

| SRA* | Anti-slip property on ceramic floor with SLS |

| SRB* | Anti-slip property on steel fllors with glycerol |

| SRC* | Anti-slip property on ceramic floor with SLS and steel on steel floors with glycerol |

| HI | sole unit provides insulation against heat |

| CI | sole unit provides insulation against cold |

| HRO | Heat-resistant outer sole |

| M | Metatarsal protection (not EN ISO 20347) |

| C | Conductive footwear |

| I | Electrically insulating footwear |

| WR | Water resistance |

| CR | Cut resistance of the upper |

| AN | Ankle protection |

| Resistance to fuel oil (only EN ISO 20347, basic requirement for EN ISO 20345) |

* = One of the three anti-slip property requirements must be selected